Rotogravure printing

NEW MACHINES FOR HIGHLY EFFICIENT, DIGITALLY CONTROLLED ROTOGRAVURE PRINTING OF FLEXIBLE PACKAGING

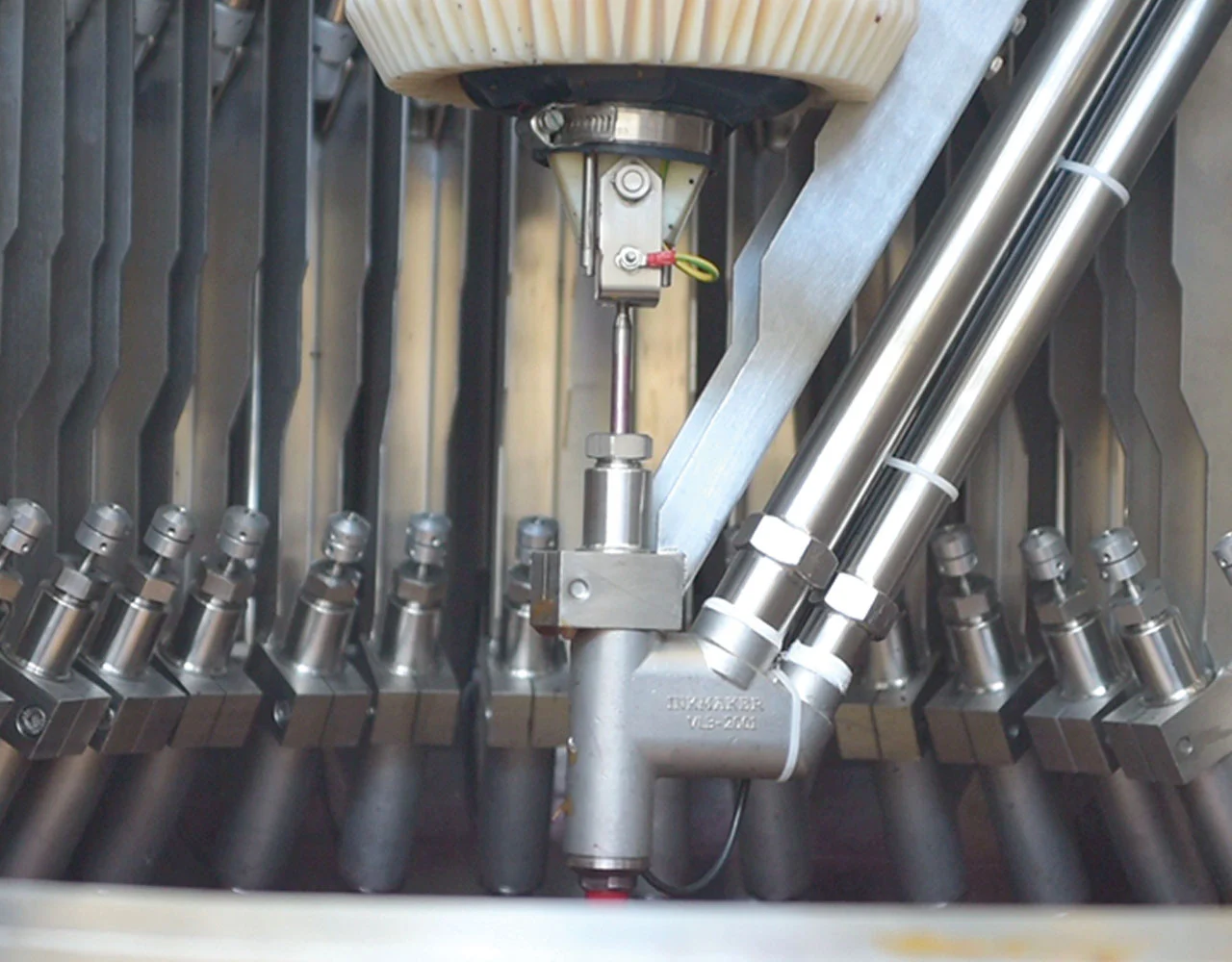

A 10 color-BOBST RS 6003C HS machine has recently been integrated into the department dedicated to rotogravure printing of flexible packaging, thus bringing the higher efficiency new double-flow air drying system to Poplast.

Thanks to this outstanding technology, it is possible to reduce the length of the drying chambers, making the performance of other machine functions more efficient while enhancing the overall efficiency of the plant.

In the «cylinder image carrier» printing mode, with direct transfer via engraved cylinders, the rotogravure printing department makes use of 3 printing machines:

- 1 machine offering the possibility of applying regulable external paints – 8 colors

- 2 machines offering the possibility of applying regulable external paints – 10 colors

Max. printing board: 1290 mm

Max. printing format: 980 mm

ROTOGRAVURE DIGITAL PRINTING CONTROL

All our machines are equipped with modern control systems for print defects, in-line control of barcode reading, and off-line control of color tones with the most modern instruments currently available in the market.

The machines are also equipped with an ESA electrostatic system, which provides excellent printing quality on paper and plastic films, especially in the half-tones and more difficult shades.

The Rotogravure department is equipped with a Mix Station for the formulation and IT storage of color recipes so as to guarantee constant printing tones over time.

WE THINK GREEN THANKS TO OUR SOLVENT RECOVERY PLANT

To reduce atmospheric emissions, the department is equipped with a modern solvent recovery plant so that solvent can be recycled in the department.